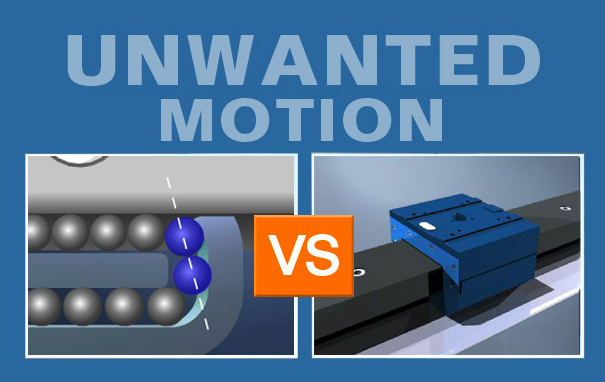

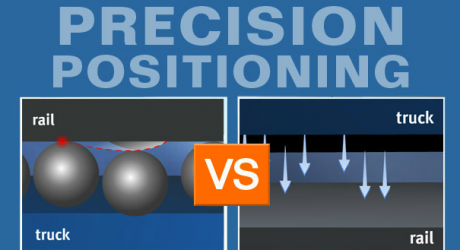

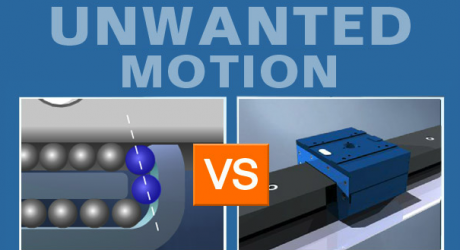

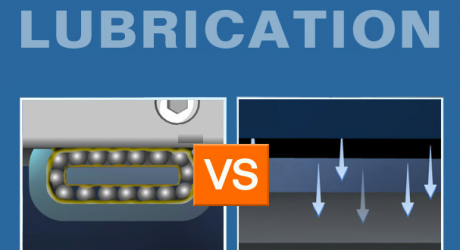

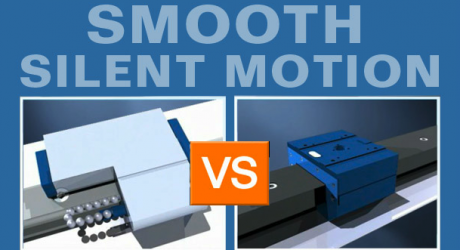

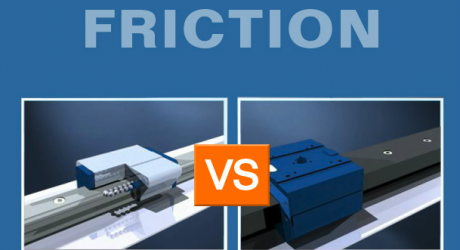

A direct comparison of porous media air bearings and conventional rolling element bearings shows that, when using the latter, there is a significant amount of unwanted motion in all directions. This is because there are minute differences in the size of the balls themselves and the balls are also slightly larger then the clearance in their bearing race. Further, the balls that enter the rail and the ones that leave the rail are not synchronized. There are always slight divergences.

More importantly, these errors are not predictable, so no controller can completely compensate for this unwanted motion.

The same is not true when using porous media air bearings. Again, there is no contact and there are no internal moving parts, only smooth and Frictionless Motion®️